Our process is simple, proven, and results in one of the strongest, longest-lasting man-made structures in the world—a dome.

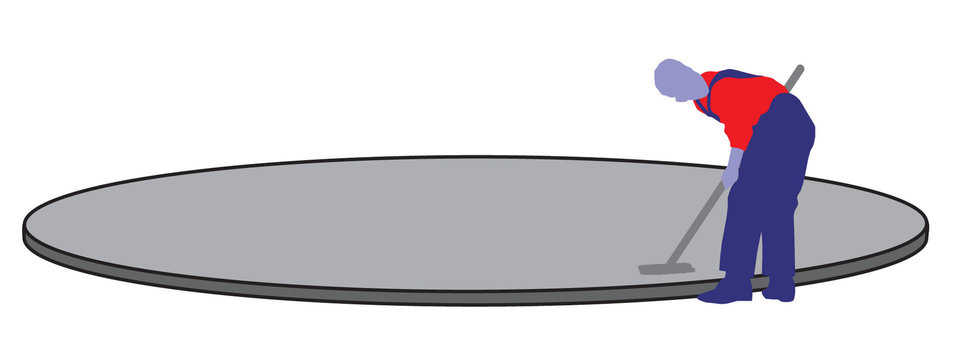

We start our dome construction by pouring a steel-reinforced circular concrete foundation. Vertical steel bars that we embed in the concrete at this stage will later get tied into the reinforcing steel rebar within the dome itself.

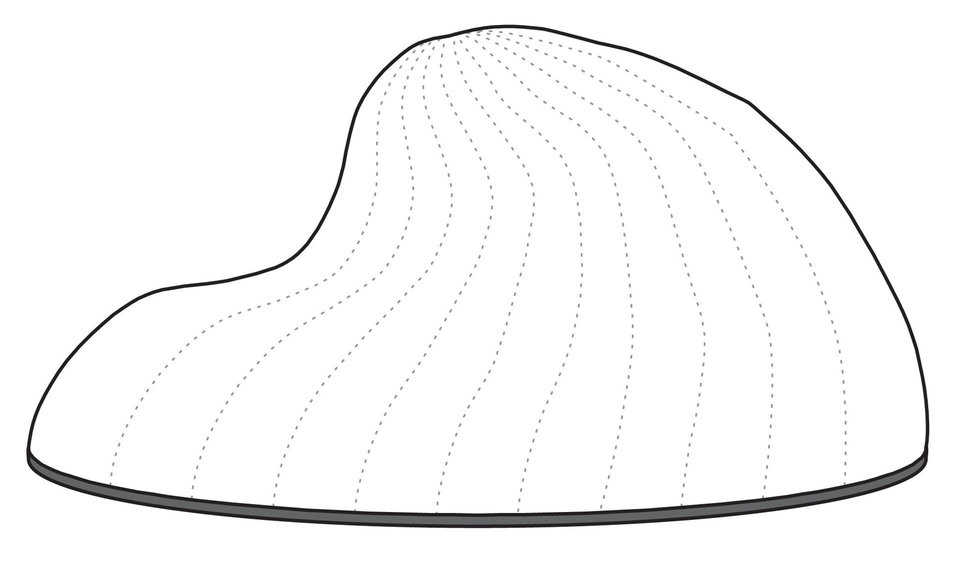

Next, we inflate a custom-fabricated Airform over the foundation to the home’s specified size and shape. Using powerful fans, we inflate the Airform, which creates the dome shape of the structure.

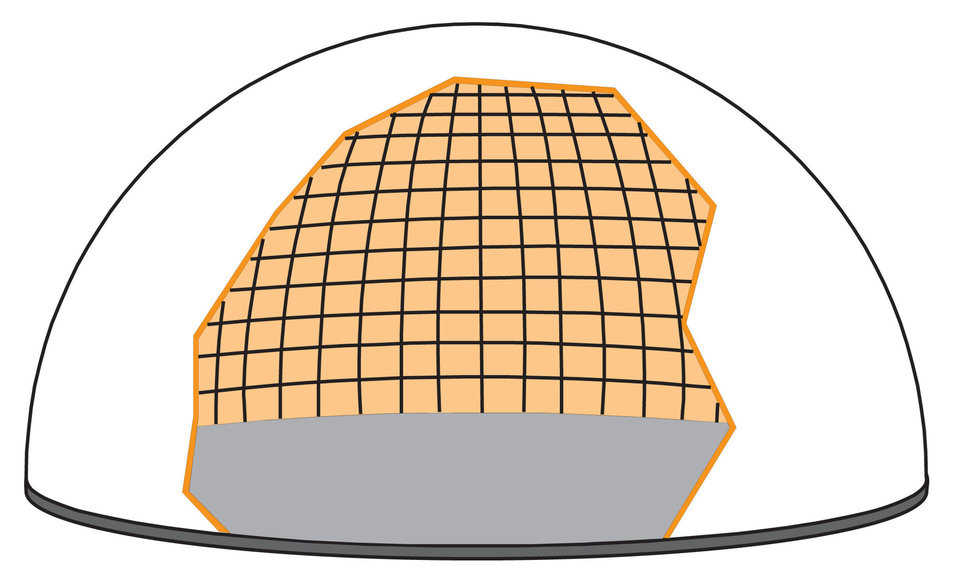

Once the Airform has taken shape, we spray the form’s interior with approximately three inches of polyurethane foam.

This foam layer also serves as the base for applying steel-reinforcing rebar while providing a high degree of insulation.

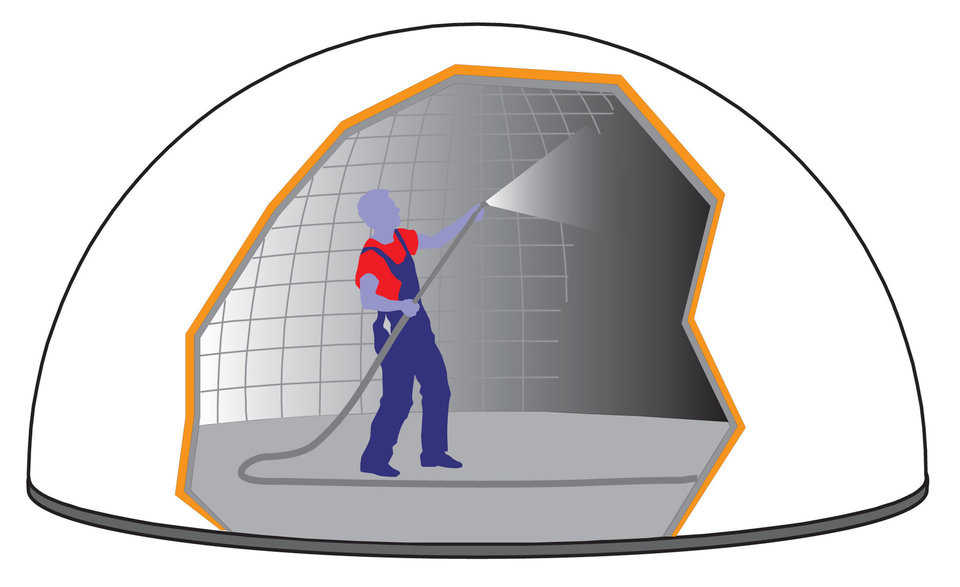

After the foam sets and the reinforcing rebar has been installed, we apply approximately three inches of shotcrete—a unique mixture of sprayable concrete—to the dome’s interior. Once the concrete sets, the structure is complete. At this point, concrete is either left bare, painted, or plastered to achieve the desired aesthetic.

Providing expert commercial, residential, and decorative concrete construction services in Sioux Falls, South Dakota.