As technology advances, the construction industry is finding new ways to improve efficiency, reduce cost, and provide more eco-friendly approaches to building homes, businesses, and infrastructure. One of the newest technologies to arise is 3D concrete printing.

While it’s still relatively new, 3D printed concrete shows some promising benefits. Still, there are obstacles it must overcome before it sees widespread adoption.

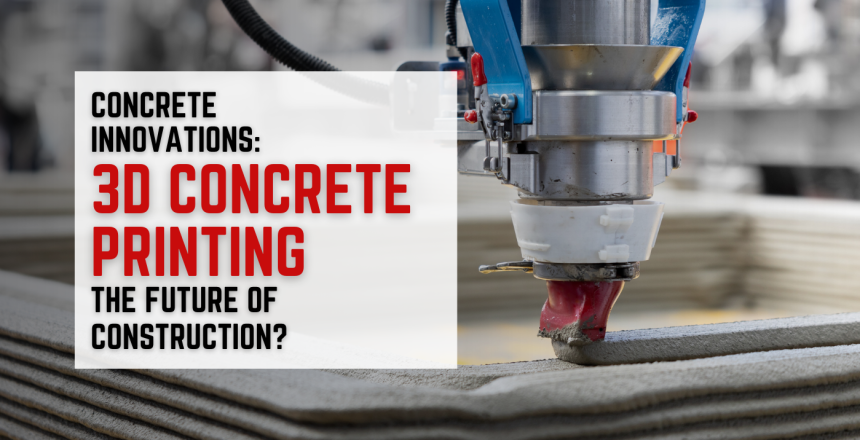

What Is 3D Concrete Printing?

Much like small-scale 3D printing with plastic filament, 3D concrete printing uses computer-guided machines to build layers of concrete material. The difference is the size of the printing machines and the materials used in them. For concrete printing, machines extrude a concrete-like paste or mortar that binds together as it cures.

At this time, there are several different technologies, along with several different 3D concrete companies, developing methods that meet the basic building requirements, although there are still questions as to how strong, flexible, and durable this new building method can be.

Materials

Instead of conventional concrete, almost all 3D printable concrete uses unique materials like plasticizers, polymers, clays, sand, and fibers for reinforcement. Most of these materials are proprietary formulas, some of which are guarded closely by the companies that developed them.

Machines

The machines used to print 3D concrete are either run on a gantry or a robotic arm system. The gantry crane system can print complex shapes in the same way a typical plastic filament 3D printer works.

Robotic arm printers work similarly, but they may not be as capable of making larger structures. In both cases, the machines are guided by computer programs that translate three-dimensional digital designs into real-world structures.

Local Sourcing

While many 3D printable concrete materials are proprietary formulas, there are a few companies dedicated to designing all-purpose dry-mix bases that can be added to local materials. This local sourcing reduces cost and transportation needs.

Curing

Because the 3D concrete printing material is not conventional concrete, companies have reduced curing time with the use of various technologies. Plasticizers replace much of the water in these mixes, reducing drying and curing times. Other mixes implement UV light curing technology in place of conventional chemical curing.

Pros of Concrete Printing

According to concrete printing companies, the 3D printing process comes with many advantages. By uncoupling from conventional Portland cement-based concrete, 3D concrete printing companies have been able to address these concerns with innovations that wouldn’t work in traditional concrete construction.

Eco-Friendly

3D concrete printing reduces waste since the process uses only the concrete necessary for the design. But even more impressive is the reduction in carbon emissions. Some mixes cut CO2 emissions by as much as 32%.

Still, these claims are based on the theoretical reduction in waste materials. Today’s 3D concrete mixes require constant adjustment and customization to set and cure properly, creating additional waste materials regularly.

Reduced Cost

Concrete printing is showing great promise for reducing the cost of construction. In Dubai, a new initiative to replace conventional construction with prefabricated 3D printed homes has started. According to reports, construction costs are up to 70% lower, and material costs are up to 80% lower. From reducing material waste to decreasing the amount of on-site labor, 3D concrete printing could make construction more affordable than ever before.

More Freedom

3D modeling and printing changed fabrication rules forever for plastic-based products and creations. Likewise, concrete printing will erase some of the limitations designers have always had to work around in construction.

Curved concrete has long been a challenge in construction because of formwork limitations. But with printed concrete, there is no need for formwork. 3D concrete printing can create any number of shapes without issue, including small-radius curves and parametric designs. This opens up possibilities for architectural features and designs that were not possible before.

Less Labor Demand

A large part of the cost of construction is in labor. Conventional concrete work requires bigger crews. 3D printed concrete, however, won’t require as many people on site, nor will it require as many hours for the workers since the printing process can be

Cons of Concrete Printing

While the benefits of 3D concrete printing are enticing, it’s worth noting some disadvantages, as well as some inconsistencies in the claims made by supporters of 3D printed concrete. Much of this technology is still in trial-and-error stages, resulting in more expensive implementation and a need for custom-tailored construction techniques on every new worksite.

Building Limitations

The gantry and robotic arm machinery used in 3D concrete printing limits the scale of the projects we can currently tackle. While a 30-foot width and height allows most home construction to be completed, bigger projects are still too complex to implement routinely.

But a bigger limitation is the fact that almost every construction project requires a unique mix to overcome environmental challenges. Changes in temperature, humidity, moisture, and weather can change the mix requirements on site. The only way to beat that challenge is to have a specialist available at all times.

There are also still questions about the strength and durability of 3D concrete printing. Benchmarking tests have shown wide variations in various areas, from around half the strength performance of conventional concrete to slightly more. That variation depends on the materials used, the machinery used, and the environmental conditions in which the printing is done. That much variation, though, makes it difficult to confidently build structures at scale.

Building Code Issues

At this time, ISO and ASTM standards help guide construction using 3D concrete printing, but local and national codes aren’t written with concrete printing in mind. In many cases, the codes don’t account for the variation in design and architectural integrity that 3D printed concrete inherently carries. Until building codes take these differences into account, contractors and companies working with 3D concrete printing will need to educate officials and find compromises that meet requirements without sacrificing the unique qualities of 3D printing.

High Initial Investment

The cost savings of 3D printed concrete may be significant, but the initial investment could still make it a high point of entry for many companies. The computer systems and actual printing equipment are still very expensive compared to conventional construction equipment, and with limited applications at this time, those costs don’t always have the return on investment needed within a workable time frame.

Additionally, since 3D printed concrete is intentionally designed to overcome specific problems and pain points, many concrete companies will find it unnecessary for their business needs.

Patented Materials and Machines

The current 3D concrete market is built on proprietary mortar formulas for each of the major players in the field. That means that both the machines and the materials are limited by patents and technical designs. Construction companies are unlikely to take the technology and modify it to their own needs without considerable involvement from the manufacturers.

Incompatible with Conventional Concrete

With the current focus of proprietary technology, conventional Portland cement concrete has been excluded from 3D concrete printing in almost every case. Polymers, plastics, and recycled material-based mortars have been the centerpiece of this technology. But this may change in the future.

There are some strides being made to change the market trajectory, specifically with efforts toward modifying aggregate concrete mixes so they can be used in concrete printing. But this innovation is not yet available for large-scale use.

Required Technical Expertise

Although 3D concrete printing may provide ways to reduce labor requirements in some aspects, it raises the need for more skilled labor. The technical challenges in 3D concrete construction require experienced workers, on-site technicians, and more engineering and chemical knowledge. With all these added requirements, 3D concrete printing doesn’t necessarily decrease the number of people for a construction project. It’s just changing the job descriptions to a more specialized labor force.

The Future of Construction with 3D Concrete Printing

Today, 3D concrete printing is still a relatively new technology. Certain communities and nations are investing in and implementing 3D printed concrete for residential and commercial buildings, including the United Arab Emirates. Dubai hopes to shift construction of new homes to prefabricated concrete printing techniques in the next decade.

But the engineers developing this technology see bigger applications in the near future.

Infrastructure

Innovations in concrete printing are already changing infrastructure engineering. Bridge construction is one of the places 3D concrete printing makes a significant difference. With the ability to create stronger shapes that are not possible with conventional formwork, engineers can design bridges that maintain their strength with less material.

Residential and Commercial

Concrete printing is already being applied to residential buildings, but commercial buildings will be the next big step. Larger builds will come as technology improves, although there are still many hurdles to overcome. Prefabricated designs may also improve construction processes, as concrete printing can be done off-site and then transported into place. Prefabricated concrete and construction are seeing more interest, and 3D printing may play a role in that trend.

Interplanetary Construction

Sever 3D concrete printing companies have developed local-source mortar mixes that can reduce construction costs for local builders. But that same development has sky-high hopes in interplanetary applications. The same mixes could be used to build on the moon, or on Mars, as interplanetary travel and colonization gains interest.

Concrete Printing for Brooks?

While the advantages are appealing on paper, the truth of the matter is that current technologies aren’t meeting the demands of our local communities. And the practical applications of 3D concrete printing have yet to meet up with the claims in terms of financial, ecological, and workforce benefits. We’re still decades away from seeing concrete printing find widespread use, either here in South Dakota or nationwide.

Instead, we’re focusing our efforts on specializations in curved concrete, large-scale projects, and concrete domes. The advantages in agricultural, manufacturing, and residential applications far outweigh the potential of 3D printed concrete at this time. Our communities are looking for green solutions to problems like grain and material storage, safety, and green investments like RNG digesters. And as long as our communities need these solutions, Brooks is here to help our local farmers, manufacturers, and homeowners meet those needs!