Agricultural business is often a low-margin market, so it’s important to make the most of your investments wherever possible. Grain storage is one of the places where cost can be decreased, and profit increased, if it’s done right. Concrete dome grain storage solutions are new to the grain industry, but they come with some amazing benefits that can’t be found in traditional silos and storage bins.

Temperature and Humidity Control in Concrete Dome Grain Storage

The highest priority in corn storage and soy bean storage is climate control. Both crops are sensitive to changes in moisture levels and temperature fluctuations, and either can ruin a crop quickly. Concrete dome grain storage solutions naturally eliminate both of these issues.

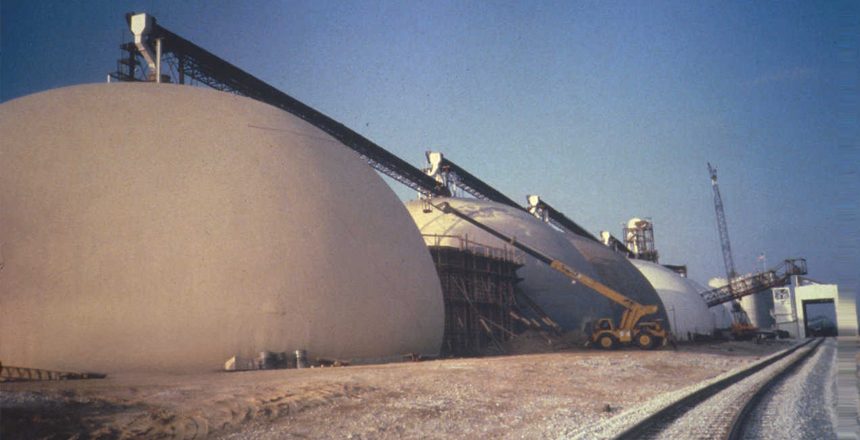

With its three-layer technology, a concrete dome grain storage structure offers an unbeatable moisture barrier. The all-weather PVC airform exterior provides an airtight seal, while the spray foam insulation almost completely eliminates temperature differences between the exterior and interior of the dome, preventing condensation inside.

The ring foundation of the dome can also be insulated, reducing ground temperature fluctuations. With an aeration system connected to temperature and humidity sensors, you can be confident that your corn storage and soy bean storage will remain safe, clean, and ready to ship to market.

Smaller Footprint, Stronger Storage Solution

The cost of land plays a role in the profit margins for corn and soy bean sales, so it’s no surprise that grain storage solutions take into account the need for higher volume structures. Again, concrete dome grain storage offers a solution like no other traditional storage structure. And a great deal of that advantage rests in the engineering itself.

While traditional silos can’t be filled to the top, a concrete dome grain storage structure’s reinforced concrete shell can be completely filled without damage. It’s simple math, really: the dome provides strength under pressure instead of pushing force into weak spots. Not only is the shape important, but the seamless design plays a role in this. Without weak spots like bolt holes, fasteners, and welds, a concrete dome can carry much greater loads than traditional storage solutions. This same design feature also means that concrete domes can withstand some of the worst winds and weather conditions nature can throw at them. They can even survive tornados and 100mph straight-line winds without suffering damage. Conventional metal silos, on the other hand, simply crumple in these extreme conditions.

When required, concrete dome grain storage structures can also be built upwards, providing more vertical storage than silos with the same footprint. Even simply building a dome in place of a circle ground pile can double or triple the available storage capacity. Although a greater initial investment in many cases, concrete dome structures quickly pay for themselves through their increased storage volume.

Unrivaled Grain Storage Throughput

With products like soy beans, throughput is a crucial part of the cost equation. High-throughput crops can cause great stress to structures as they’re loaded and emptied repeatedly. In traditional structures, this leads to damage, maintenance, and time loss. Concrete domes, however, do not suffer the same issues. Instead, their steel-reinforced concrete walls evenly distribute weight and force during these throughput cycles.

Depending on the throughput rates necessary, these structures can be engineered to include solutions that range from augers to vibrating floor throughput solutions. Even the transport from storage to customers can play a role in the customized design of these domes. With front-end engineering, companies and farmers can minimize cost, maximize throughput, and see greater profits from start to finish.

Concrete dome storage structures can also be designed with flow solutions built in. Whip chain systems, air cannons, and screw reclaimers can all be utilized to break up compacted piles, especially with oily grains. This means greater safety and fewer hiccups in the throughput process.

Concrete Dome Storage Reduces Foundation Requirements

A typical grain bin or silo requires deep pilings to maintain its structural integrity. Not so with concrete dome grain storage systems. The ring foundations used in the construction process create a solid footing that can reduce the required piling depth, or even eliminate the need for pilings altogether. In terms of structural strength, concrete domes can stand firmly on less even ground and with less earthwork to set the foundation. In terms of cost, there is less material, less time, and less labor to create the same or greater structural integrity of a smaller traditional structure. In either case, domes mean a greater return on investment in much less time.

A Food Safe Solution for Corn and Soy Bean Storage

Food safety standards are a key part of food storage. With concrete dome grain storage structures, corn and soy beans can remain safe for transport and use, even after long periods of storage. Temperature stability and moisture control are just part of a reliable food-safe storage facility.

The seamless construction of concrete domes provides incredible protection against crop loss due to insects and animals of all sorts. No cracks, weak spots, or holes in the body of the structure equal fewer points of entry for these pests, translating to less chance of contamination for the grain.

And concrete domes can be customized to meet specific food safety measures. Whether it’s a specific interior coating or stainless steel equipment, food grains like corn and soy can stay safe in these unique storage solutions.

A Complete Solution for Corn and Soy Bean Storage

Traditional storage solutions have several shortcomings, but concrete domes offer solid solutions to many of the greatest limitations of metal structures. The seamless construction process and materials eliminate moisture and temperature concerns, keeping soy beans and corn, as well as other grain crops, safe from condensation and contamination. Even more, the steel-reinforced concrete offers unrivaled strength for heavy throughput requirements. Even repeated emptying and filling has little effect on the integrity of concrete dome grain storage structures. And with the most mathematically efficient shape for strength and storage capacity, domes can store more with a smaller footprint. Each of these innovations provides benefits for grain storage, but together they add up to less loss and more profit.

If you’re looking for a grain storage solution that outlasts and outperforms traditional structures, concrete dome construction should be at the top of your list. We provide customized solutions for any need. Request more information via our website, or call to make an appointment to discuss your needs or take a tour of our facility, including a model concrete dome home. Our agricultural engineers can help you find the perfect solution for your storage needs.